Hubei Yulong Group Jinli New Materials Co., Ltd.

Address:

Dongcheng Road #23, Yiling District, Yichang City, Hubei, China 443100

Tel/ fax:

+86-0717-7805388

Wechat/Whatsapp:

+86 13477858967

Email: rosie.xiao@ylfrp.net

History:

First developed in the mid 1930's, Glass Fiber Reinforced Plastic (GFRP) has become a staple in the building industry. Originally used merely for the construction of parts, in 1967, the architectural advantages were discovered with the attempted destruction of Disneyland's "House of the Future." Built in 1956-7, the futuristic house was built entirely of fiberglass, and when the attraction was no longer deemed necessary, it was scheduled to be destroyed in 1967. Amazingly, the wrecking ball merely bounced off the structure, and the possibilities for GFRP were recognized and began to grow. By 1994, nearly 600 million pounds of composite materials were used in the building industry. Today,Architectural provides a variety of products in GFRP to fit your building needs and aesthetic vision.

Fabrication:

YULONG in-house design and drafting teams work closely with you, the client, to capture your idea on paper. Once all the drawings have been approved, our sculptors carve a model to your specifications.

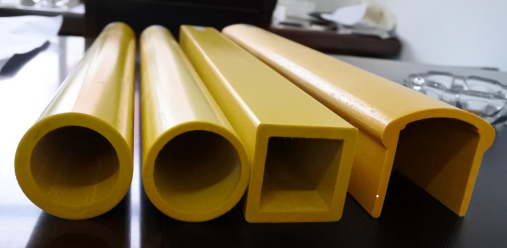

A mold is then made of fiberglass, steel, wood or rubber depending on the detail. Into this mold a carefully designed mix of polyester or epoxy resin is sprayed, along with alkali resistant glass fibers. Virtually any shape or form can be molded.

Applications

GFRP can be used for both interior and exterior fixtures in a variety of shapes, styles, and textures; in new buildings or restorative projects.

§ Domes

§ Fountains

§ Columns

§ Balustrade

§ Planters

§ Panels

§ Sculpture

§ Entryways

§ Moldings

§ Facades

§ Cornice

§ Porticos

§ Cupolas

§ Signs

§ Roofs

Why GFRP?

High Strength

GFRP has a very high strength to weight ratio.

Lightweight

Low weights of 2 to 4 lbs. per square foot means faster installation, less structural framing, and lower shipping costs.

Resistance

Resists salt water, chemicals, and the environment - unaffected by acid rain, salts, and most chemicals.

Seamless Construction

Domes and cupolas are rosined together to form a one-piece, watertight structure.

Able to Mold Complex Shapes

Virtually any shape or form can be molded.

Low Maintenance

Research shows no loss of laminate properties after 30 years.

Durability

GFRP stood up to category 5 hurricane Floyd with no damage, while nearby structures were destroyed.